About

Bambu Lab P2S Combo 3D Printer – Multi-Color Printing

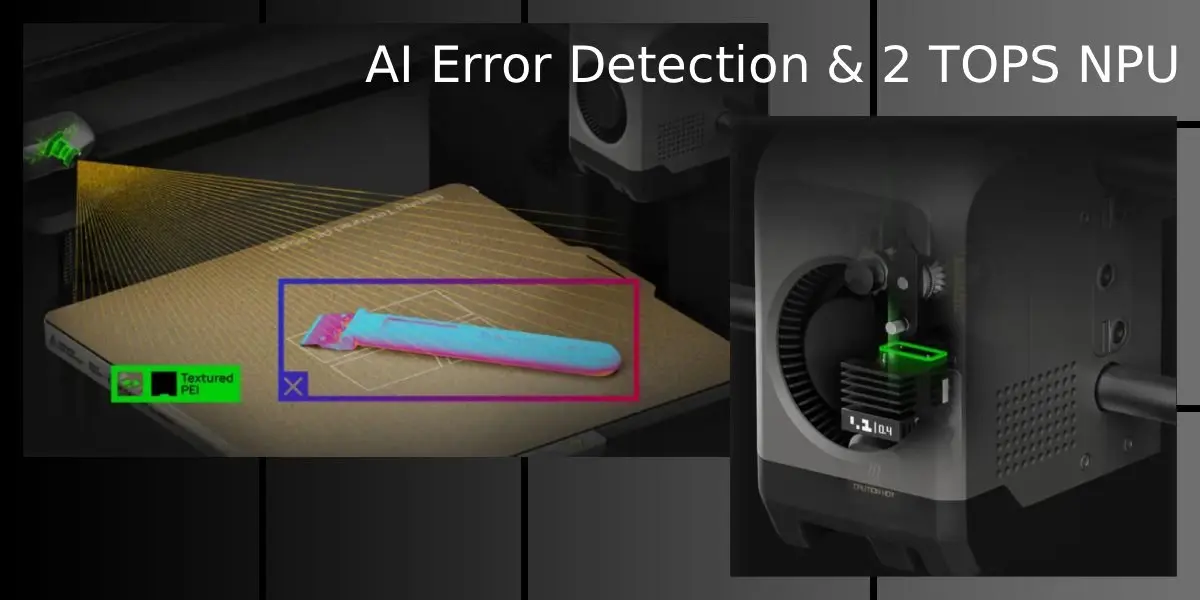

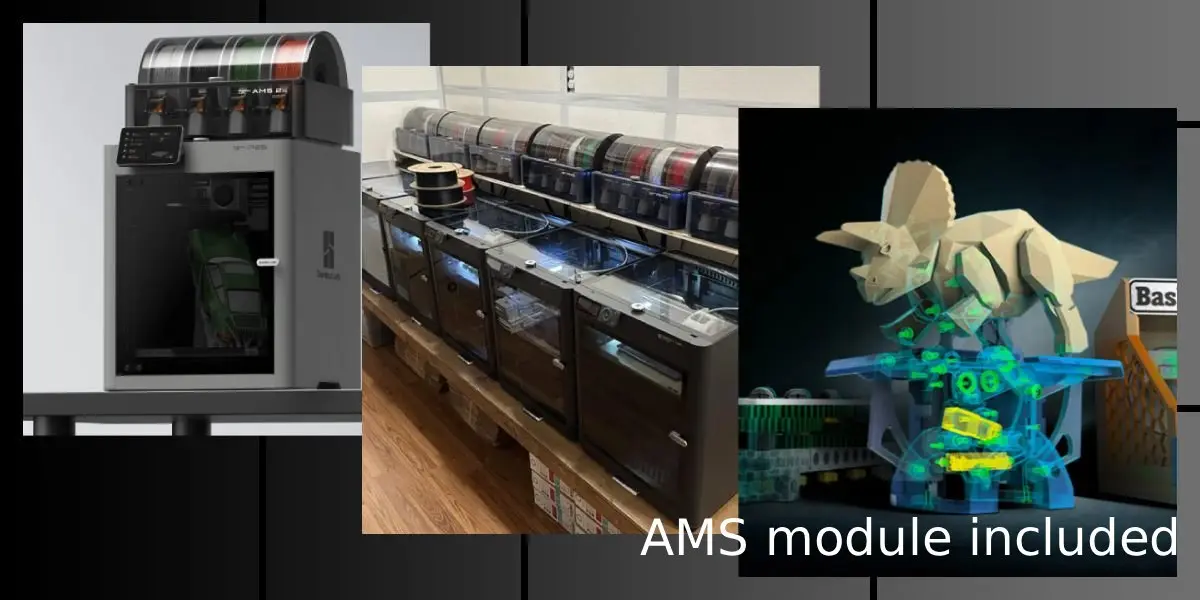

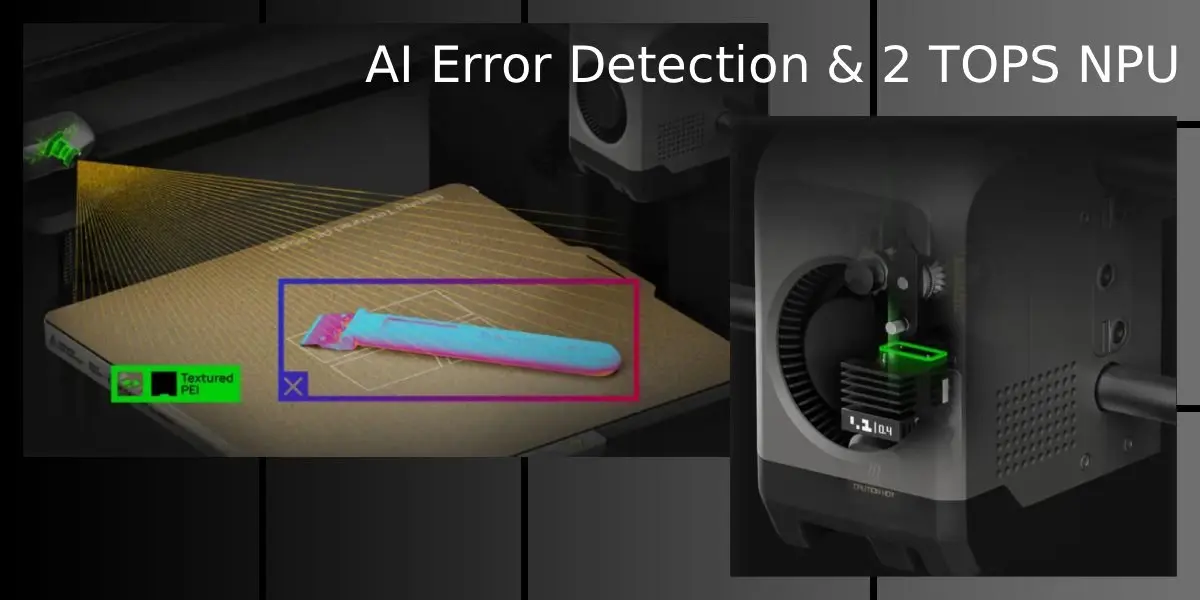

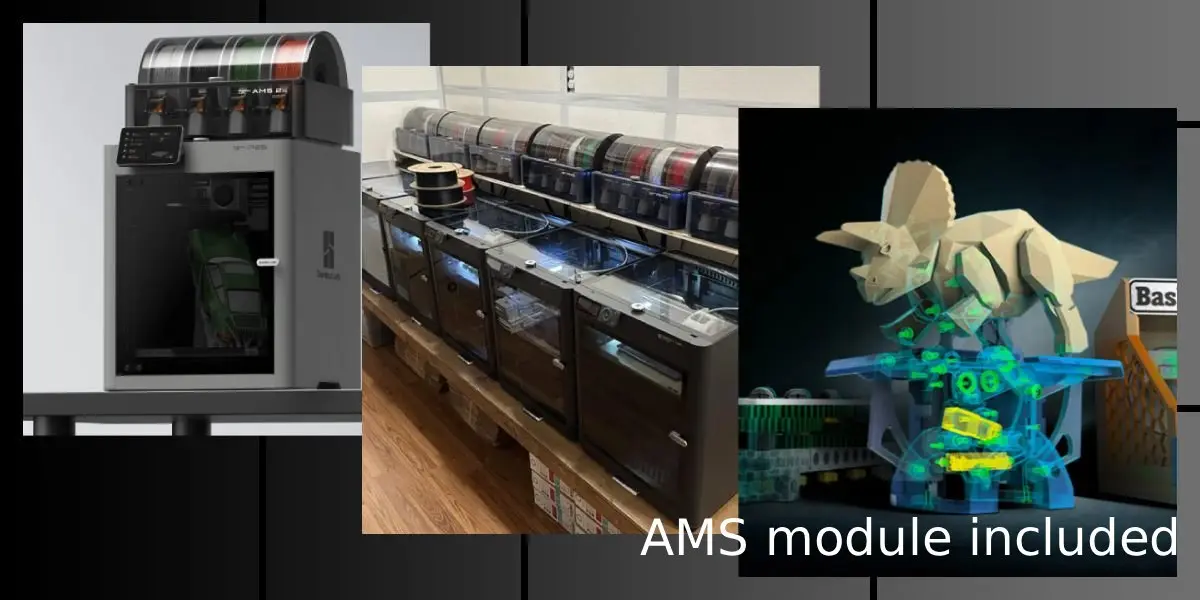

The P2S Combo model includes the AMS module, which allows printing with different materials or a single material in various colors. Filament feeding and changing occur automatically. You need to properly set up the P2S Combo before starting the print, and then it works autonomously. A number of innovative engineering solutions not only automate the printing processes but also help avoid errors and failures using AI.

Key Technical Properties and Characteristics

The Bambu Lab P2S Combo 3D printer is a high-performance and reliable desktop machine for three-dimensional printing that combines expert technology and user convenience.

- The build volume is 256 × 256 × 256 mm, allowing you to work with sufficiently large parts while maintaining the compact dimensions of the device.

- The printer is built on the Core-XY scheme, which ensures fast and precise movement of the print head. The device uses a modern PMSM extruder (servo-drive) with a force of up to approximately 8.5 kg, which significantly increases filament feeding stability and allows working with highly complex materials.

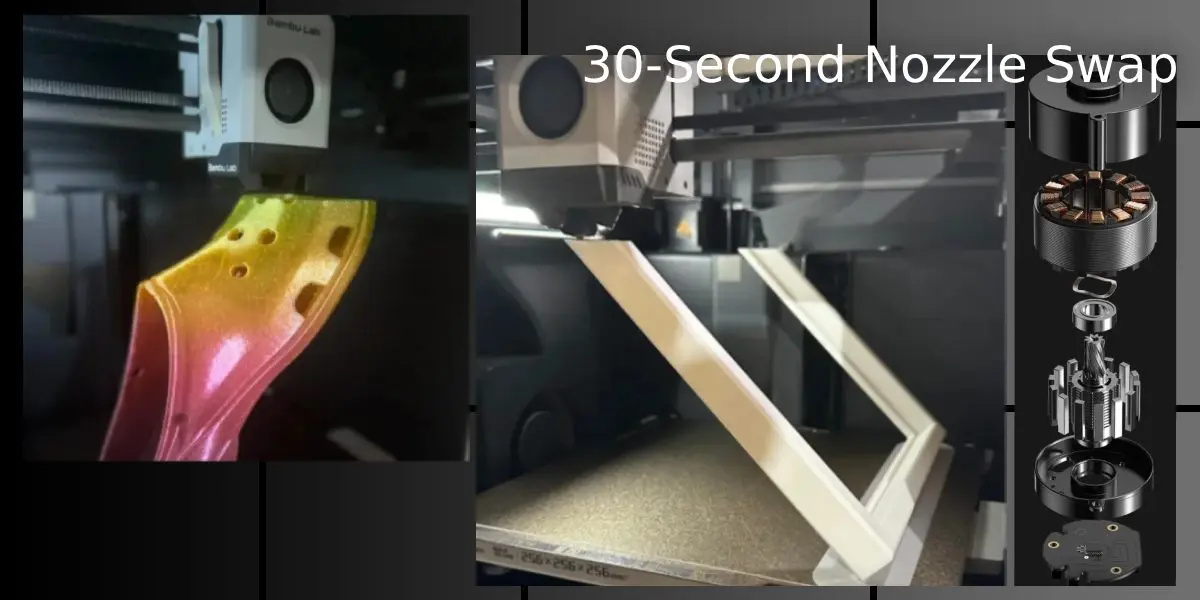

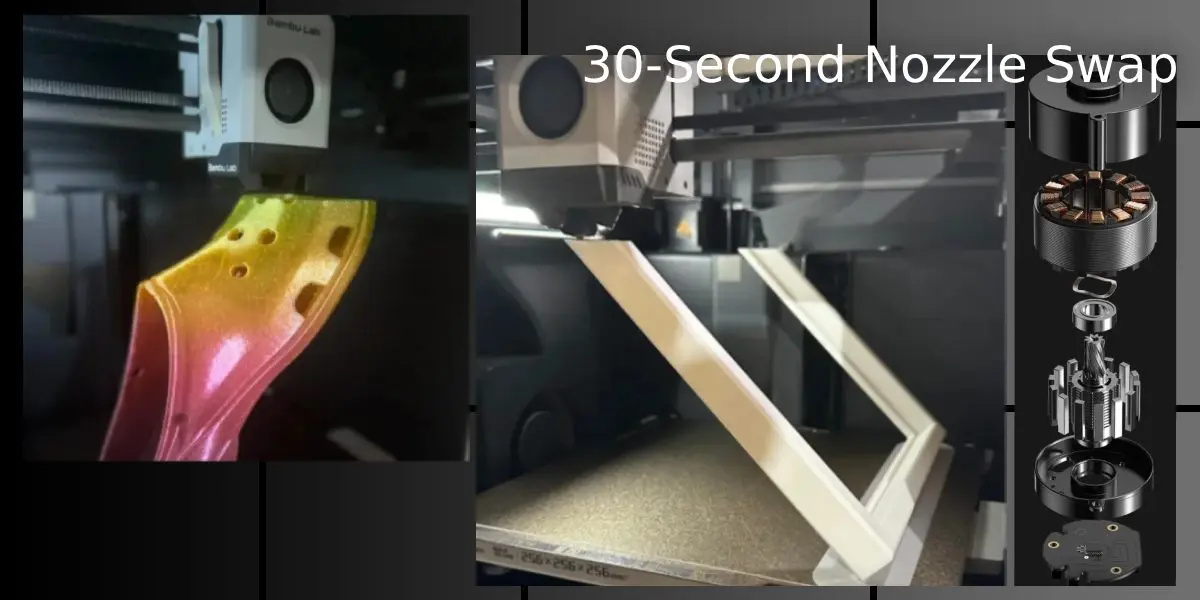

- The default nozzle diameter is 0.4 mm made of hardened steel, which is suitable for most tasks; if necessary, 0.2 mm, 0.6 mm, and 0.8 mm diameters are supported.

- The maximum extruder temperature is up to 300 °C, which allows the use of a wide range of engineering and composite materials.

- The heated bed can reach a temperature of 110 °C, making it possible to print with materials prone to warping.

- The device body is enclosed, and an Adaptive Airflow system with a carbon filter is implemented, which allows controlling the thermal regime inside the chamber and filtering the air — especially important when working with engineering materials.

- The interface is a 5-inch touchscreen with the proprietary second-generation user interface, making control convenient even for users without extensive experience.

- A built-in 1080p camera with lighting is included for remote monitoring function, as well as an intelligent system for detecting printing errors (such as "spaghetti printing," clogged nozzle, and others).

- Materials supported by the model: PLA, PETG, TPU, ABS, ASA, PA, PC, and composite filaments with fillers (carbon and glass fiber).

- The physical dimensions of the machine are approximately 392 × 406 × 478 mm, weight — around 14.9 kg.

- The kit includes the Printer itself + the filament changing/drying system (AMS 2 Pro) in the Combo version.

These technical characteristics make the P2S Combo a universal tool for both hobby projects and small-batch production, ensuring a high level of accuracy, reliability, and flexibility.

What distinguishes the Bambu Combo from the base P2S version

The base P2S version already represents an update to the lineup: compared to the previous P1S model, it received enhancements in interface, extruder, airflow, and automation.

However, the «Combo» suffix in the name Bambu Lab P2S Combo specifically denotes a kit that expands the capabilities of the base machine. That is, if the P2S is the printer itself, the P2S Combo is the printer with the included automatic material feeding and changing system (AMS 2 Pro) and other additions optimized for multi-color and multi-material printing.

Thus, the key difference: the base P2S is powerful on its own but requires additional modules for extended material handling; in the P2S Combo version, these modules are already included, ensuring readiness for more complex tasks "out of the box."

Features and advantages of the P2S Combo version

The kit includes the AMS 2 Pro system (Automatic Material System 2 Pro) — its presence provides automatic filament changing, built-in drying, and the ability to work with multiple spools/colors simultaneously. This gives a significant advantage for multi-color and multi-material printing.

- Ability to configure up to 20 spools of filament via AMS modules — convenient for complex projects with multiple colors or materials.

- Fast nozzle change and high printing stability thanks to the Quick-Swap system, servo extruder drive, and pressure sensors, which minimizes downtime and errors.

- Improved extrusion accuracy and stability — thanks to the high-frequency eddy-current sensor, the device automatically corrects the filament flow, ensuring uniform printing even on complex geometries.

- Support for engineering materials and composites — while many functions may be limited in the standard version, the Combo version is initially designed for expanded freedom of plastic choice, which is especially important for serious applications.

- Ease of use: proprietary interface, auto-leveling, WiFi connectivity, camera monitoring — all this lowers the barrier to entry even for less experienced users, while providing a premium level.

- Compactness and versatility: despite the advanced hardware, the P2S Combo remains a sufficiently compact device for placement in a workshop or small production space.

Areas of use for the P2S Combo model

The P2S Combo version is excellent for the following scenarios:

- Creating prototypes and functional test samples during the development phase, when high accuracy and the ability to quickly change material or color are required.

- Small-batch production of parts: thanks to the ability to work with engineering materials and composites, final operational products can be produced.

- Educational and laboratory tasks: ease of operation, safety of the enclosed chamber, and intelligent features make it attractive for educational institutions and research centers.

- Hobby workshops and design studios: the ability to print bright, multi-component objects with color transitions or combined materials (e.g., carbon-filled PETG) makes it sought after by designers and enthusiasts.

- Production of accessories and customized items: thanks to the volume and functionality, parts for robots, drones, engineering devices, and decorative elements can be created with a high level of detail.

- The inclusion of AMS 2 Pro means that printing can be organized almost like a factory process: monitoring, spool changing, combining colors and materials — all available in one device.

Technical Specifications of the Bambu Lab P2S Combo 3D Printer

| Parameter | Value |

|---|---|

| Build Volume (W×D×H) | 256 × 256 × 256 mm |

| Maximum Nozzle Temperature | Up to 300 °C |

| Heated Bed | Up to 110 °C |

| Default Nozzle Diameter | 0.4 mm (supports 0.2 / 0.6 / 0.8 mm) |

| Extruder | Servo-PMSM, force up to ~8.5 kg |

| Supported Materials | PLA, PETG, TPU, ABS, ASA, PA, PC, composites |

| Camera and Monitoring | 1080p camera for time-lapse and remote control |

| Interface | 5″ touchscreen, 2nd generation UI (Bambu Lab Blog) |

| Contents | Printer + filament changing/drying system (AMS 2 Pro) in the Combo version |

Quick tips for choosing consumables

- Start with PLA: this material is maximally simple to print, does not require an activated chamber or bed heating above 110 °C. A good choice for mastering the printer.

- PETG and ASA: the next step — if you want stronger parts and resistance to temperature or UV light. Make sure to adhere to recommended temperatures and use a build plate with good adhesion.

- TPU (flexible plastic): suitable, but requires caution — check that the extruder is set for slower loading and avoid abrupt movements, as flexible filament can "jam."

- Composites (carbon fiber, glass fiber): require a hard nozzle (hardened steel or carbide) and appropriate settings. The P2S Combo is ready for such tasks thanks to the high-strength extruder and hardened nozzle.

- Filament Drying: especially for PA, PC, and composites — moist filament can lead to defects. The Combo version has a built-in drying system (AMS 2 Pro), and it is recommended to store spools in sealed containers or drying devices.

- Spools with RFID chips: if original manufacturer filaments are used, the machine automatically recognizes the type, color, and remaining amount — ensuring more precise preparation. However, third-party filaments can also be used — just experiment with the settings.

- Build plate and adhesion: a textured PEI plate is included in the kit, but for difficult materials (e.g., ABS, PA), you should use either a special adhesive layer or a removable "CoolPlate SuperTack" build plate.

If you are looking for a 3D printer that combines high performance, accuracy, ease of use, and powerful multi-material/multi-color functionality, then the Bambu Lab P2S Combo offers the optimal solution. Thanks to the Combo version, you get everything you need "out of the box": not just a printer — but a complete platform for serious three-dimensional printing, whether it's prototyping, small-batch production, or creative experiments. Its technical specifications, ease of operation, and growth potential make it an excellent choice for both experienced users and those who want to step up to the next level.

Bambu Lab P2S Combo 3D Printer – Multi-Color Printing

The P2S Combo model includes the AMS module, which allows printing with different materials or a single material in various colors. Filament feeding and changing occur automatically. You need to properly set up the P2S Combo before starting the print, and then it works autonomously. A number of innovative engineering solutions not only automate the printing processes but also help avoid errors and failures using AI.

Key Technical Properties and Characteristics

The Bambu Lab P2S Combo 3D printer is a high-performance and reliable desktop machine for three-dimensional printing that combines expert technology and user convenience.

- The build volume is 256 × 256 × 256 mm, allowing you to work with sufficiently large parts while maintaining the compact dimensions of the device.

- The printer is built on the Core-XY scheme, which ensures fast and precise movement of the print head. The device uses a modern PMSM extruder (servo-drive) with a force of up to approximately 8.5 kg, which significantly increases filament feeding stability and allows working with highly complex materials.

- The default nozzle diameter is 0.4 mm made of hardened steel, which is suitable for most tasks; if necessary, 0.2 mm, 0.6 mm, and 0.8 mm diameters are supported.

- The maximum extruder temperature is up to 300 °C, which allows the use of a wide range of engineering and composite materials.

- The heated bed can reach a temperature of 110 °C, making it possible to print with materials prone to warping.

- The device body is enclosed, and an Adaptive Airflow system with a carbon filter is implemented, which allows controlling the thermal regime inside the chamber and filtering the air — especially important when working with engineering materials.

- The interface is a 5-inch touchscreen with the proprietary second-generation user interface, making control convenient even for users without extensive experience.

- A built-in 1080p camera with lighting is included for remote monitoring function, as well as an intelligent system for detecting printing errors (such as "spaghetti printing," clogged nozzle, and others).

- Materials supported by the model: PLA, PETG, TPU, ABS, ASA, PA, PC, and composite filaments with fillers (carbon and glass fiber).

- The physical dimensions of the machine are approximately 392 × 406 × 478 mm, weight — around 14.9 kg.

- The kit includes the Printer itself + the filament changing/drying system (AMS 2 Pro) in the Combo version.

These technical characteristics make the P2S Combo a universal tool for both hobby projects and small-batch production, ensuring a high level of accuracy, reliability, and flexibility.

What distinguishes the Bambu Combo from the base P2S version

The base P2S version already represents an update to the lineup: compared to the previous P1S model, it received enhancements in interface, extruder, airflow, and automation.

However, the «Combo» suffix in the name Bambu Lab P2S Combo specifically denotes a kit that expands the capabilities of the base machine. That is, if the P2S is the printer itself, the P2S Combo is the printer with the included automatic material feeding and changing system (AMS 2 Pro) and other additions optimized for multi-color and multi-material printing.

Thus, the key difference: the base P2S is powerful on its own but requires additional modules for extended material handling; in the P2S Combo version, these modules are already included, ensuring readiness for more complex tasks "out of the box."

Features and advantages of the P2S Combo version

The kit includes the AMS 2 Pro system (Automatic Material System 2 Pro) — its presence provides automatic filament changing, built-in drying, and the ability to work with multiple spools/colors simultaneously. This gives a significant advantage for multi-color and multi-material printing.

- Ability to configure up to 20 spools of filament via AMS modules — convenient for complex projects with multiple colors or materials.

- Fast nozzle change and high printing stability thanks to the Quick-Swap system, servo extruder drive, and pressure sensors, which minimizes downtime and errors.

- Improved extrusion accuracy and stability — thanks to the high-frequency eddy-current sensor, the device automatically corrects the filament flow, ensuring uniform printing even on complex geometries.

- Support for engineering materials and composites — while many functions may be limited in the standard version, the Combo version is initially designed for expanded freedom of plastic choice, which is especially important for serious applications.

- Ease of use: proprietary interface, auto-leveling, WiFi connectivity, camera monitoring — all this lowers the barrier to entry even for less experienced users, while providing a premium level.

- Compactness and versatility: despite the advanced hardware, the P2S Combo remains a sufficiently compact device for placement in a workshop or small production space.

Areas of use for the P2S Combo model

The P2S Combo version is excellent for the following scenarios:

- Creating prototypes and functional test samples during the development phase, when high accuracy and the ability to quickly change material or color are required.

- Small-batch production of parts: thanks to the ability to work with engineering materials and composites, final operational products can be produced.

- Educational and laboratory tasks: ease of operation, safety of the enclosed chamber, and intelligent features make it attractive for educational institutions and research centers.

- Hobby workshops and design studios: the ability to print bright, multi-component objects with color transitions or combined materials (e.g., carbon-filled PETG) makes it sought after by designers and enthusiasts.

- Production of accessories and customized items: thanks to the volume and functionality, parts for robots, drones, engineering devices, and decorative elements can be created with a high level of detail.

- The inclusion of AMS 2 Pro means that printing can be organized almost like a factory process: monitoring, spool changing, combining colors and materials — all available in one device.

Technical Specifications of the Bambu Lab P2S Combo 3D Printer

| Parameter | Value |

|---|---|

| Build Volume (W×D×H) | 256 × 256 × 256 mm |

| Maximum Nozzle Temperature | Up to 300 °C |

| Heated Bed | Up to 110 °C |

| Default Nozzle Diameter | 0.4 mm (supports 0.2 / 0.6 / 0.8 mm) |

| Extruder | Servo-PMSM, force up to ~8.5 kg |

| Supported Materials | PLA, PETG, TPU, ABS, ASA, PA, PC, composites |

| Camera and Monitoring | 1080p camera for time-lapse and remote control |

| Interface | 5″ touchscreen, 2nd generation UI (Bambu Lab Blog) |

| Contents | Printer + filament changing/drying system (AMS 2 Pro) in the Combo version |

Quick tips for choosing consumables

- Start with PLA: this material is maximally simple to print, does not require an activated chamber or bed heating above 110 °C. A good choice for mastering the printer.

- PETG and ASA: the next step — if you want stronger parts and resistance to temperature or UV light. Make sure to adhere to recommended temperatures and use a build plate with good adhesion.

- TPU (flexible plastic): suitable, but requires caution — check that the extruder is set for slower loading and avoid abrupt movements, as flexible filament can "jam."

- Composites (carbon fiber, glass fiber): require a hard nozzle (hardened steel or carbide) and appropriate settings. The P2S Combo is ready for such tasks thanks to the high-strength extruder and hardened nozzle.

- Filament Drying: especially for PA, PC, and composites — moist filament can lead to defects. The Combo version has a built-in drying system (AMS 2 Pro), and it is recommended to store spools in sealed containers or drying devices.

- Spools with RFID chips: if original manufacturer filaments are used, the machine automatically recognizes the type, color, and remaining amount — ensuring more precise preparation. However, third-party filaments can also be used — just experiment with the settings.

- Build plate and adhesion: a textured PEI plate is included in the kit, but for difficult materials (e.g., ABS, PA), you should use either a special adhesive layer or a removable "CoolPlate SuperTack" build plate.

If you are looking for a 3D printer that combines high performance, accuracy, ease of use, and powerful multi-material/multi-color functionality, then the Bambu Lab P2S Combo offers the optimal solution. Thanks to the Combo version, you get everything you need "out of the box": not just a printer — but a complete platform for serious three-dimensional printing, whether it's prototyping, small-batch production, or creative experiments. Its technical specifications, ease of operation, and growth potential make it an excellent choice for both experienced users and those who want to step up to the next level.

Bambu Lab P2S Combo 3D Printer

- Regular price

- $799.00

- Sale price

- $799.00

- Regular price

-